Revolutionary Technology Helps Limit Human Intervention in Dangerous Environments

Last week we looked at the Innovative technology behind the invention of the ZipNut. ™ Now it’s time to find out how ZipNut Technology has been adapted to several tools to provide faster and safer ways of operating in dangerous environments.

Radiation, intense heat and deep water subsea environments are extremely dangerous to humans. Fortunately, the dark days of putting people in life-threatening danger unnecessarily are over thanks to the innovative technology of ZipNut Technology.

Through unique adaptations, standard tools are being transformed ended and now remove human interaction in dangerous areas. They’ve been found to make work safer and significantly faster in such industries as energy, nuclear, fire/rescue and aerospace.

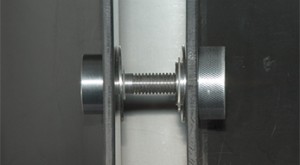

The ingenious technology behind ZipNuts allows them to replace the time-consuming and repetitive motion of threading regular nuts thanks to a special design where the ZipNut’s three, spring-loaded thread segments expand as they travel down the bolt.

When the ZipNut is tightened with a quick turn, those same thread segments are forced into the threads of the bolt thanks to the complementary geometry between ZipNut’s housing and its thread segments.

By taking the unparalleled speed of the ZipNut, which was originally developed for NASA for use on the Space Shuttle, International Space Station and used on the Hubble Telescope, and applying it to many tools in a variety of applications, work not only becomes safer but improves production through efficiency.

ZipNut Technology Tools in Action

ZipNuts are amazing inventions in their own right, but they also give birth to tools that are game changers in many industries.

In fire and rescue, ZipNut Technology’s been adapted for use in positive connection systems on oxygen bottles; mechanical rams used in auto accident victim extractions, construction accidents and building collapse; as well as rescue struts that stabilize a vehicle or light structure from collapse.

The subsea industry is also a perfect example of where ZipNut Technology is changing how business gets done.

FASTORQ developed a line of ZipNut Technology Tools that adds safety to hazardous environments but also brings increased speed and production capability with such tools as the ZipTENSIONER, F.A.S.T. System, ZipPULLER, ZipLIFT and AutoZIP VIV Machanism Fastener.

Subsea Tools

ZipTENSIONER. The ZipTENSIONER is a stud tensioner that uses Double ZipNut Technology to provide 100 percent, same side flange coverage and reduces tensioning time by up to 90 percent. Elastic interactions are eliminated, and the old standard of twisting and turning heavy and awkward standard stud tensioners is a thing of the past. ZipTENSIONERs are compact, lightweight and simply slide on and off the stud, even past damage and corrosion, to provide accurate tension with incredibly impressive speeds. The time reduction when using ZipTENSIONERs can save hundreds of thousands of dollars in just one use.

ZipTENSIONER. The ZipTENSIONER is a stud tensioner that uses Double ZipNut Technology to provide 100 percent, same side flange coverage and reduces tensioning time by up to 90 percent. Elastic interactions are eliminated, and the old standard of twisting and turning heavy and awkward standard stud tensioners is a thing of the past. ZipTENSIONERs are compact, lightweight and simply slide on and off the stud, even past damage and corrosion, to provide accurate tension with incredibly impressive speeds. The time reduction when using ZipTENSIONERs can save hundreds of thousands of dollars in just one use.

F.A.S.T. Take the ZipTENSIONER and ZipNUT Technology one step further, and you get the F.A.S.T. (Fully Automated Stud Tensioner) System. This system takes the human interaction of tensioning and completely removes it. Controlled by a single hydraulic power console, this system incorporates multiple ZipTENSIONERS into one frame that is lowered onto all of the studs on the same side of a flange. With the push of a button, all of the tensioners are simultaneously energized and the nuts turned down. Once finished, F.A.S.T. removes just as easily as it went on.

ZipPULLER. Bringing flanges together subsea can be an especially difficult task. The ZipPULLER uses ZipNut Technology to pull flanges together in an operation similar to the movement of an inchworm. By using the ZipPULLER, the need to reset the tool after each pull is removed. In this incredibly challenging subsea application, flange pulling becomes infinitely safer and more productive. It can also be used in land-based applications or anywhere heavy equipment needs positioning.

ZipPULLER. Bringing flanges together subsea can be an especially difficult task. The ZipPULLER uses ZipNut Technology to pull flanges together in an operation similar to the movement of an inchworm. By using the ZipPULLER, the need to reset the tool after each pull is removed. In this incredibly challenging subsea application, flange pulling becomes infinitely safer and more productive. It can also be used in land-based applications or anywhere heavy equipment needs positioning.

ZipLIFT. Another tool that uses Double ZipNut Technology is the ZipLIFT. It provides safe and reliable lifting strength in hazardous areas. The tool utilizes a unique segmented nut that opens while positioned on mating threads and locks onto the threaded rod with the weight of the load when lifted. It will not release the load until is has safely landed because it depends on slack in the line to allow its thread segments to disengage. The ZipLIFT been used in radioactive areas at Oak Ridge National Laboratory in Tennessee as well as other facilities and in the removal of subsea Christmas trees and BOP’s.

ZipLIFT. Another tool that uses Double ZipNut Technology is the ZipLIFT. It provides safe and reliable lifting strength in hazardous areas. The tool utilizes a unique segmented nut that opens while positioned on mating threads and locks onto the threaded rod with the weight of the load when lifted. It will not release the load until is has safely landed because it depends on slack in the line to allow its thread segments to disengage. The ZipLIFT been used in radioactive areas at Oak Ridge National Laboratory in Tennessee as well as other facilities and in the removal of subsea Christmas trees and BOP’s.

AutoZIP VIV Mechanism Fasteners.Those pesky sea currents are no match for AutoZIP VIV Mechanism Fasteners. Vortex Induced Vibration (VIV) is destructive to subsea risers and moorings. By implementing ZipNUT Technology into a fastener for VIV suppression system fairings on subsea risers; fast, permanent and irreversible fastening stops AutoZIP VIV Mechanism Fasteners from ending up on the ocean floor after hazards such as hurricanes or the long-term effects of regular VIV.

AutoZIP VIV Mechanism Fasteners.Those pesky sea currents are no match for AutoZIP VIV Mechanism Fasteners. Vortex Induced Vibration (VIV) is destructive to subsea risers and moorings. By implementing ZipNUT Technology into a fastener for VIV suppression system fairings on subsea risers; fast, permanent and irreversible fastening stops AutoZIP VIV Mechanism Fasteners from ending up on the ocean floor after hazards such as hurricanes or the long-term effects of regular VIV.

It’s no doubt that the ZipNut and ZipNut Technology Tools are revolutionary. The innovation, safety, productivity and speed they provide to many industries are so dramatic that is can even make the difference between life and death. If you are in an industry that needs to step out of the dark ages of fastening technology, it’s time to step up to the innovation of the ZipNut and ZipNut Technology Tools.

Check out a video on ZipNut and ZipNut Technology at http://www.youtube.com/watch?v=k28DdqVuqQc.

FASTORQ is the exclusive manufacturer of ZipNut Technologies for the Energy industry. FASTORQ’s innovative use of ZipNut Technology in several of its tools has increased speed, reliability and worker safety in such areas as oil exploration and production, subsea applications, nuclear energy maintenance and more.

ZipNUT is a registered Trademark of ZipNut Technologies

SEP

About the Author:

Lisa Raynor-Keck is the Marketing Communications Specialist at FASTORQ. She earned her degree in journalism from the University of Central Florida and gained her early writing experience at newspapers in Michigan and Tennessee. In addition to her press positions, Lisa's work portfolio includes experience as a freelance writer, political campaign ad designer and public relations professional. She also has experience working as an editor and writer for the technology division at Middle Tennessee State University and an articles editor for the Navy's former online military lifestyle website Lifelines. Lisa is currently studying to earn her M.A. in corporate communication at Austin Peay State University.