By Lisa Raynor-Keck

Lurking on the shelf of your shop is one of the most underestimated safety hazards you’ll encounter. It appears innocent and is often harmless until something goes wrong. Surprisingly, it’s your poorly designed flange spreader.

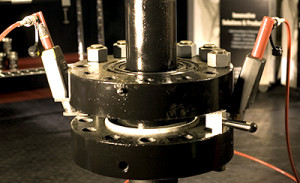

A flange spreader’s uncomplicated appearance is deceiving. Every year people are treated for injuries when seemingly adequate flange spreaders fail. The results can be anything from cuts and gashes to serious injuries. That’s why having a flange spreader that incorporates strength and safety into one unit is invaluable. FASTORQ’s AutoSPREADERS do just that!

Nearly all flange spreaders claim they are strong and safe but have no evidence to support their claims. They speak of spreading force and their ability to get into tight spaces, but do they really tell you what makes them safe when they are on the job?

FASTORQ AutoSPREADERs not only fit into gaps as small as a 3/32” and lift loads up to 10,000 lb per spreader, but also stay securely in place thanks their steel, serrated feet that won’t break off when significant spreading force is applied.

When a flange spreader dislodges from a flange it can slam shut. It is not hard to imagine all of the injuries that can occur when this happens. In addition to the flange slamming shut, the flange spreader and its parts can become projectiles and severely injure anyone in their path. You also have a damaged flange to contend with. The AutoSPREADER’s gripping power and engineered strength don’t allow these accidents to happen.

Also, when it comes to safety, the less repositioning required during load separation, the safer the load. AutoSPREADERs can also achieve up to a 3-inch gap in just one pass. Other flange spreaders cannot claim this. They need multiple passes to achieve the same gap as the AutoSPREADER.

When you add in the AutoSPREADERs safety blocks provide 1,2 and 3-inch blocking and have an easy grip handle, flange separation just became safer. These solid blocks support the load once it has achieved its desired separation.

Available in hydraulic and manual models, AutoSPREADERS are fast, easy, fit all flanges and provide all-important parallel separation. They are perfect for gasket maintenance, bearing removal, manway separation, machinery leveling and impeller removal.

Nobody wants to purposely cause injury to another person, but when choosing a flange spreader for lifting, leveling, lowering or aligning, it’s imperative to choose a flange spreader, such as the AutoSPREADER, that will do these jobs safely.

JUL

About the Author:

Lisa K. Wildman, Marketing Manager for FASTORQ, is a professional writer with more than 30 years experience. Published in nationally distributed magazines and regional and local newspapers, Lisa’s expertise focuses on the energy and housing industries. Lisa co-authored and published two award-winning books “Building the American Dream: A Consumer’s Guide to New Home Construction” and “Remodeling the American Dream: A Consumer’s Guide to Home Renovation.” During her career, Lisa served as Editor-in-Chief for “Florida Styles Magazine” and “Southern Impressions” both dedicated to the residential construction industry.