By Lisa Raynor-Keck with Louie Durdin

By Lisa Raynor-Keck with Louie Durdin

Stud tensioning jobs are often long and exhausting processes that eat up valuable man hours and tie up equipment. At best, 50 percent of the studs are tensioned at one time with conventional stud tensioners. It’s time to ask yourself, is there a better way?

ZipTENSIONER Double Zip Stud Tensioners are the solution. They cut job time by more than half compared to other standard tensioners. The one-piece design provides 100-percent project coverage and allows for simultaneous tensioning on multiple fasteners. In addition, it evenly loads all fasteners in the joint and eliminates elastic interactions (commonly referred to as cross talk) while providing a compact, light and low-profile design.

In the case of conventional stud tensioners, they are assembled on the bolts and puller nuts are threaded onto fasteners that are often in very bad condition with rusted or damaged threads. The FASTORQ stud tensioner works by using spring-loaded thread segments that allow the tensioner to slide over the protruding stud threads, which eliminates the time-consuming task of threading the puller nut. Rusted or damaged threads are also less of an issue with the FASTORQ Stud Tensioner since threading the puller nuts is bypassed.

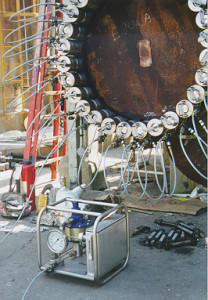

Above: A channel head cover on a shell and tube heat exchanger at a Hydrocracker unit in a popular refinery. In the past, the 28 bolts in the cover, measuring 2 1/2″ in diameter, were torqued using hydraulic torque wrenches. It took more than 14 hours to complete bolt preload to the prescribed torque value. Elastic interactions (cross talk) caused the long torque time. Over the course of multiple turnarounds, the flange typically leaked during the required hydrostatic test. This usually required an additional four to six hours to stop the leak. When engineers determined that tensioning was the best way to shorten the bolt preload time and eliminate leaking during the hydrostatic test, FASTORQ’s ZipTENSIONER provided the solution.

Designed for subsea, nuclear and wind turbine industries, the ZipTENSIONER Double Zip StudTensioner is customizable and a great option for other industries in need of improved stud-tensioning speed, such as offshore, petrochemical, steel and mining.

The ZipTENSIONER Double Zip Stud Tensioner performs at optimum levels when used with the FASTORQ HTP2000 Power Unit. However, it provides significant reduction in tensioning time when used with non-FASTORQ power units as well.

All parts are durable, provide corrosion protection and come with FASTORQ’s Total Assurance Guarantee and 3-Year Warranty.

Click the link for additional information on the FASTORQ ZipTENSIONER Double Zip Stud Tensioner.

FEB

About the Author:

Lisa K. Wildman, Marketing Manager for FASTORQ, is a professional writer with more than 30 years experience. Published in nationally distributed magazines and regional and local newspapers, Lisa’s expertise focuses on the energy and housing industries. Lisa co-authored and published two award-winning books “Building the American Dream: A Consumer’s Guide to New Home Construction” and “Remodeling the American Dream: A Consumer’s Guide to Home Renovation.” During her career, Lisa served as Editor-in-Chief for “Florida Styles Magazine” and “Southern Impressions” both dedicated to the residential construction industry.