Tailor-Made Tools Make the Impossible Possible

Do you ever find yourself in a situation where nothing seems to work? Is off-the-shelf not good enough? Then, a custom designed tool is your answer.

Custom designed tools are intended to go beyond the capabilities of standard stock designs and are tailor-made to work well for your challenging job.

When you are in need of a custom solution, it is important to find a company that specializes in custom tool design solutions engineered for your difficult job, like FASTORQ. The company should also be familiar with the requirements and complexities of your industry, whether as subsea, nuclear, wind, mining, manufacturing and oil and gas.

Your custom solutions tool company should also have a successful history of solving customer challenges, whether large or small projects.

Examples of Custom Solutions

Don’t Drop the Nut

A customer needed to break loose and remove 3-1/8-inch nuts from a flange 100 feet beneath the ocean surface with the use of an ROV. The challenge was that the nuts could not drop to the ocean floor.

A FASTORQ SpinTORQ IL360-308 with a custom magazine was used for the challenge. The SpinTORQ quickly removed the nuts and stored them in the magazine. The customer was so happy with the custom solution; they scheduled more special designed SpinTORQs for future jobs.

Subsea Bolting Challenge

In another project, a customer needed six strakes bolted to a spar. (A strake mitigates the effects of vortex-induced vibration, or underwater current, on the spar or hull of the offshore drilling vessel.) This had never been done before “after the fact” since spars typically have the strakes bolted to them before the platform is installed.

In another project, a customer needed six strakes bolted to a spar. (A strake mitigates the effects of vortex-induced vibration, or underwater current, on the spar or hull of the offshore drilling vessel.) This had never been done before “after the fact” since spars typically have the strakes bolted to them before the platform is installed.

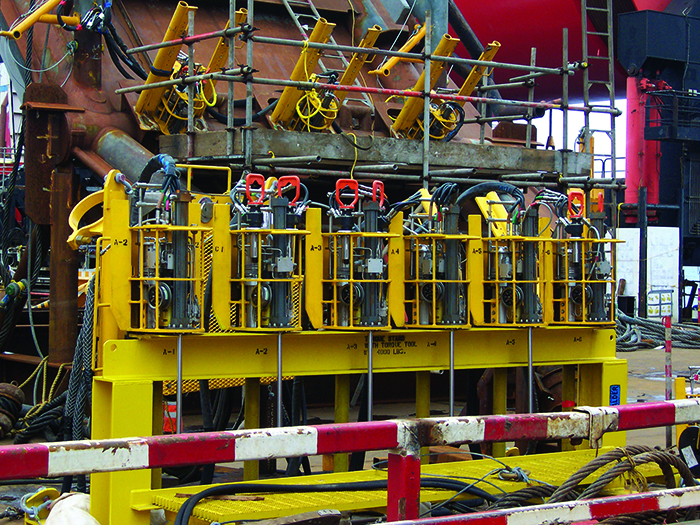

The challenge involved bolting these strakes to the spar with no subsea diver. The deepest point in the project was about 300 feet. That is when ZipTENSIONERs were used to handle the challenge.

ZipTENSIONERs worked with a power control console to accomplish the job. All operational control was managed topside using the console and an Observation Class ROV as the eyes.

The project entailed specially manufactured 50-foot pins that needed to secure the strake to the spar. Each pin included three, 3-inch ZipNuts. The tensioners preloaded with the 3-inch studs inside, were deployed while mounted on the strake. As the strake was put into position on the pin, the tensioners were lowered. Tension was applied to the studs and successfully locked the strake bolt in place.

When Size Matters

A refinery customer needed to remove 6-1/8-inch nuts in high-pressure head exchangers on a hydrocracker fast without damaging the studs. The challenge involved building a nut splitter to cut through extremely large nuts.

A refinery customer needed to remove 6-1/8-inch nuts in high-pressure head exchangers on a hydrocracker fast without damaging the studs. The challenge involved building a nut splitter to cut through extremely large nuts.

Prior to this custom solution, the largest nut splitter available handled only 5-3/8-inch nuts. To solve this challenge, FASTORQ custom built the AutoSPLITTER AS608 to handle the job. It is now available for anyone to order.

Then came the challenge of developing a nut splitter for a project that needed 7-1/2-inch round nuts split. FASTORQ rose to the challenge and developed a custom nut splitter to handle this especially difficult job.

Challenges come from everywhere. Whether it is a channel head that won’t stop leaking or an enormous nut needs split, difficult challenges will always be around. However, when they happen, know you need an innovative custom solutions partner to get you through your tough projects with ease.

FASTORQ has accepted the challenge presented by their customers to develop custom tools for difficult applications since 1981. When looking for a custom solutions partner, look no further than FASTORQ.

NOV

About the Author:

Lisa Raynor-Keck is the Marketing Communications Specialist at FASTORQ. She earned her degree in journalism from the University of Central Florida and gained her early writing experience at newspapers in Michigan and Tennessee. In addition to her press positions, Lisa's work portfolio includes experience as a freelance writer, political campaign ad designer and public relations professional. She also has experience working as an editor and writer for the technology division at Middle Tennessee State University and an articles editor for the Navy's former online military lifestyle website Lifelines. Lisa is currently studying to earn her M.A. in corporate communication at Austin Peay State University.